Everything you need to know about synchronous hydraulic pump station

A hydraulic power network is a series of linked pipes that transport pressurized liquid from a power source, such as a pump, to hydraulic equipment, such as lifts or motors. The system is similar to an electrical grid that transmits power from a power plant to end customers. Hardly a few hydraulic power transmission systems are in use today; contemporary hydraulic equipment includes a pump. A hydraulic network could have been employed in a factory in the late nineteenth century, with a central steam engine as well as water turbine operating a pump and a series of high-pressure pipes delivering power to various machinery.

Pump Stations and Their Functions

Pumps, motors, as well as a pump control system, manifolds, and valves make up a synchronous hydraulic pump station. Pump stations are quite complex due to their hydraulics and electrical controls, but in a nutshell, they are built up to give a specific flow of liquid at a specified pressure to transfer the fluid from the beginning point to all targeted places. Pump stations may be fitted up in a number of ways to ensure that they function properly. A pump station, for example, might contain a main pump and just a backup pump, or two main pumps as well as a single backup pump, or three main pumps and no backup pump.

Of course, while selecting the right set-up for each system, the magnitude of the system, cost, and allowable downtime minus fluid flow are all aspects to consider. There are many distinct types of pumps that may be found in any given system. When looking at pump stations, you can come across end suction, submersible, vertical turbine, as well as vertical multi-stage centrifugal pumps, to name a few.

Double-acting synchronous quantitative hydraulic pump features include:

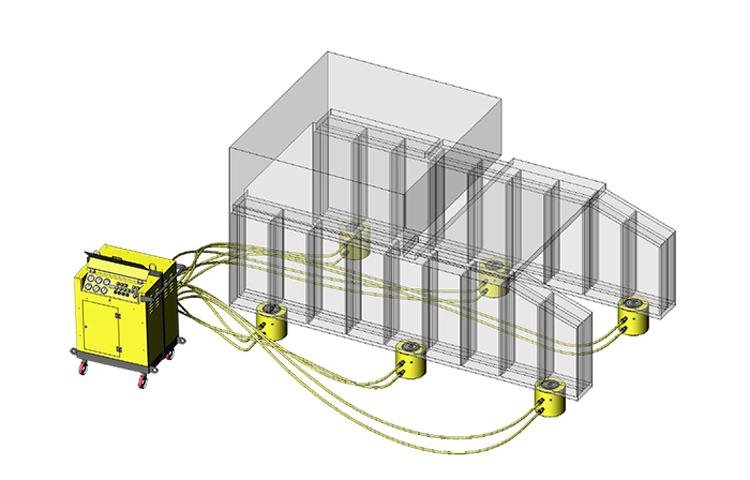

The quantitative synchronous pump station is developed to satisfy the needs of customers under synchronous lifting load operating conditions. Four separate oil supply valves are inserted in the pump body as a result of improvements to the construction of the standard hydraulic pump station. The four pistons have the same specifications and models, and they share a single motor, ensuring that the oil supply amount of each plunger to the jack is the equal.

Each plunger has a three-position, four-position hydraulic pump fitted at the oil supply exit. The jack may be individually regulated to raise, fall, and stop at four places using the solenoid valve as well as hydraulic control one-way valve.

There are operating buttons for separate control as well as connection control of the four points in the electrical control section, as well as an emergency stop switch to regulate the jack when it is simultaneously lifted. The single point modification control operation can be used if there is a large synchronous mistake in the lifting process; due to the jack’s processing acceptance, the duration of the oil pipe, the balance of the load, as well as other variables, the synchronous control precision of this pump station is usually about 5mm. The pump station cannot be used to regulate the lowering of large items in a simultaneous manner. The electric pump’s surface is painted and has excellent anti-corrosion and anti-pollution properties. It has a small and light design. It may be used as a walking automobile (two universal wheels, with brake function, two directional wheels). On both sides, there are guardrails, which are useful for oil pipe installation, high pressure, and huge flow. It may be used with a huge tonnage jack. It has an adjustable pressure valve, that makes recalibrating operating pressure as well as preventing pressure overload a breeze.

Contains: The pump body is supplied with four separate oil supply plungers, all of which have the same specs and models and are powered by the same motor, ensuring that each plunger receives the same oil supply from the jack.

Hydraulic jack with four points of synchronous control.

Best Companies that provide hydraulic pumps

- Riverlake is a combination of the founder’s parents’ hometown names: Sichuan Province (River) and Hubei Province (Lake). Taizhou Chuanhu Hydraulic Machinery Co, Ltd. was founded by Tang Lianhua in 2005 as a maker of high-pressure hydraulic tools in China. Hydraulic lifting cylinders, bearing pullers, hydraulic pumps & power packs, flange spreader tools, hydraulic nut breakers, hydraulic workshop press, hydraulic torque wrench, bolt tensioner tool, bolt tensioner pump, hydraulic torque wrench power pack, and more are among their major goods. Their goods have been shipped to various nations and locations, including the United States, South Asia, and Africa, due to their excellent quality and professional service. They now produce in Yuhuan Longxi Industrial Zone, Zhejiang province, at various facilities with a total area of 5.000 m2 and 50 people.

- “AL – Ameen Enterprises” was founded in 1987 and is one of the leading providers of HYDRAULIC EQUIPMENTS in the Eastern Region and throughout India.

They have been able to create a place for their products in the industry thanks to the important assistance of their partners Mr. Mohammed 9830120822, Mr. Zakir Husain, and Mr. Iqbal Husain. Their artistic business sense, noteworthy expertise, open transactions, and inspiring demeanour have allowed them sustain worldwide excellence standards in their product line while also attracting a large customer base.